First of all, let's first understand what is the UV curing machine. The UV curing oven is a machine that uses the UV lamp light source to generate heat to dry the curing surface. UV light curing machine is used for paper, PVC, plastic products using UV spray, after printing ink layer curing. It is the more environmentally friendly ink drying method. It can excite the UV lamp to emit ultraviolet light with a main peak of about 360 nm under the excitation of a transient high voltage, and irradiates the acrylic resin crosslinked and cured by the ink on the ink layer.

Impurities contained in quartz glass include hydroxyl (OH), aluminum, calcium, magnesium, sodium, potassium, iron, cobalt, boron, etc. The total amount of impurities is generally less than 0.02%. The most harmful impurities are hydroxyl (OH), potassium and sodium. Hydroxyl (OH) During the lighting process, the quartz is in a high temperature state, penetrates into the lamp, and the penetration increases with increasing temperature. Permeating into the interior of the tube, the hydroxyl group decomposes into water, hydrogen and oxygen at high arc temperatures. The water circulation in the lamp transports the electrode tungsten to both ends of the lamp, and the tube wall appears deuterated. It is difficult to start the lamp to accelerate the aging of the lamp. Potassium and sodium devitrify quartz under high temperature, making quartz opaque, and the light emitted by the lamp is absorbed by the crystal of quartz glass, causing the lamp to age.

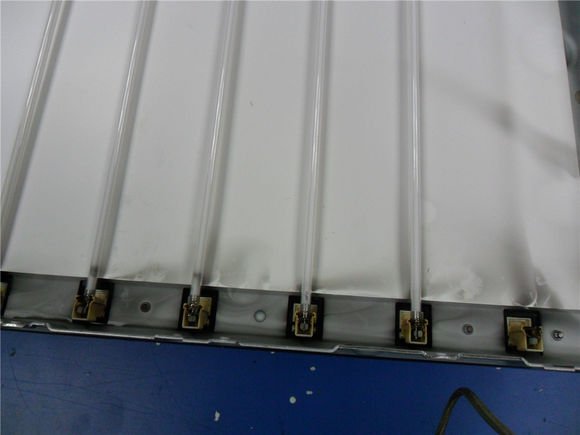

Therefore, good ventilation, RF admittance position so that the lamp tube end in the best working condition, the temperature is lower than 500 °C, can improve the lamp life.

Use the following points should be noted:

A. Transformer parameters and lamp parameters must be matched. Voltage and current must not exceed design specifications. In particular, the starting voltage should not be too high, generally not exceeding 40% of the design operating voltage.

B. Keep the wall clean, especially remove oil and dust. Because these substances will penetrate into the lamp tube on the surface of the high-temperature tube, blocking the ultraviolet radiation.

C. Ventilation is scientific and reasonable. The amount of ventilation should be scientifically calculated. The purpose of the electromagnetic flowmeter is to suck the heat generated by the UV lamp out of the lamp, so that the lamp can work under the normal temperature environment, not the lower the temperature, the better. Ventilation keeps the lamp head temperature below 150°C. In addition, with a reasonable amount of air flow, the temperature of the line, sensor, and case of the light box is kept below 90°C.

HUIYUE (DongGuan City) Automation Equipment Co., Ltd.

HUIYUE (DongGuan City) Automation Equipment Co., Ltd.